The Advanced Supplier of Scaffolding Steel Prop

iMW(iMetalwork) scaffolding manufacturer mainly do Scaffolding Steel Props, Safety Gate, Trap Door, Frame, Base Jack, Steel Plank, Cuplock System, Aluminum Beam, Brace and any other scaffolding welding parts. All parts of scaffolding props are produced by ourselves, which can guarantee the delivery time and quality of each order of customers. All of our production equipment are the world’s top brands. All inner tubes of the scaffolding prop are laser cut instead of punched with a regular punch. All our welders meet EU welding quality requirements. The welding machine is a Panasonic welding machine. So the scaffolding props each weld seam perfectly.

All products from iMW(iMetalwork) are subject to strict production process inspection and pre-shipment inspection. Each time delivered is equipped with special supervisors for on-site supervision and guidance to ensure the smooth operation of the loading.

In the past ten years, iMW(iMetalwork) has always adhered to the customer demand-oriented; relying on the pursuit of high quality products, timely and efficient service to customers won the reputation of the market. In the future, we will continue to work hard to provide the best quality service to our global customers.

Production Process of Scaffolding Steel Prop

Inner tube: Cutting Tube→ Punching→ Welding Bottom Plate.

Outer tube: Cutting Tube→ Rolling Threaded Tube→ Punching Oval Hole→ Welding Threaded Tube→ Welding Bottom Plate.

Accessories: G pin→ Forged Pin→ Nuts (coated sand/precision casting)→ Handles.

Surface Treatment: Hot-dip galvanized.

Assembly→ Reaming→ Labeling→ Palletizing (steel tape) →Labeling→ Loading Container→ Make Inspection Photos→ Make Loading Photos.

Production Process of Scaffolding Steel Prop

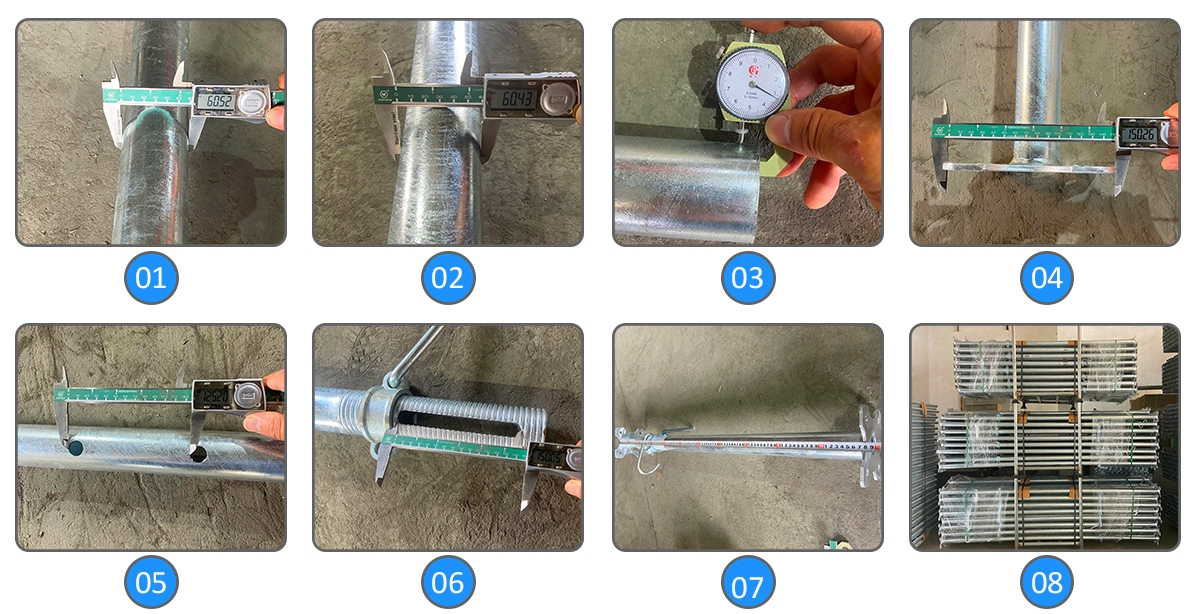

After the raw materials arrive at the factory, we will first conduct the first inspection of the raw materials, and only after all the dimensions meet the product specifications will they be officially put into production. The whole production process is supervised by professional producers. Each time a production process is completed, corresponding dimensional and quality inspections will be carried out. The data and results of each process inspection will be reported and entered into the system one by one. After each size of the final product has no problem, an inspection report of scaffolding prop will be made according to the detailed pictures of the inspection and provided to the customer, and finally the product will be packaged and loading container.

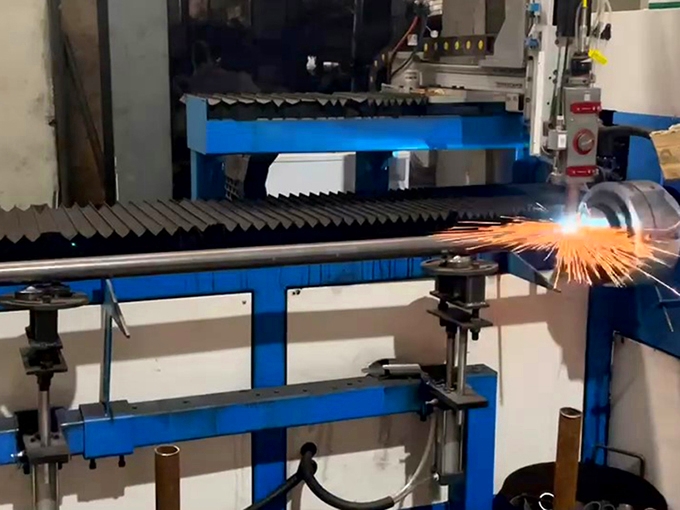

Scaffolding Steel Prop Laser Cutting

All inner tubes of the scaffolding prop are laser cut instead of punched with a regular punch. All our welders meet EU welding quality requirements.

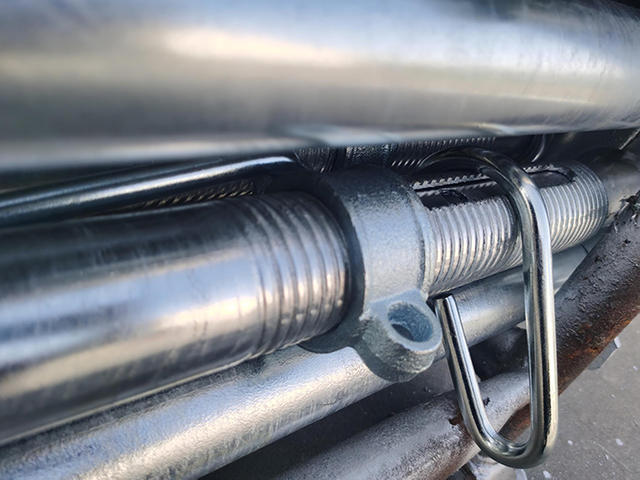

Heavy Duty Scaffolding Props Inner Tube Reaming

For heavy scaffolding steel props, we ream the inner pipe of the scaffolding props according to the actual requirements of customers, which can ensure that the inner pipe will not fall off during use, which is more convenient for operators to use during construction and improve product safety.

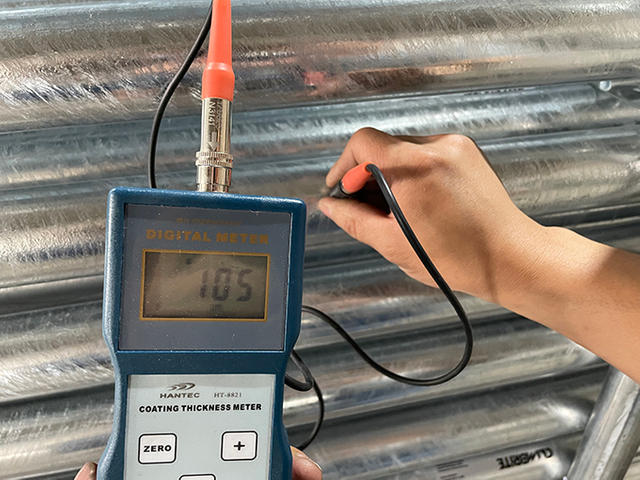

Measurement of Hot-dip galvanized Prop Zinc Thickness

Scaffolding Steel Prop Pallet Packing Details

In order to ensure the stability of the pallet after scaffolding props are packed, each pallet is bound and fixed with steel straps.

Scaffolding Steel Props Loading

When the production of the steel prop ordered by the customer is finished and all the packaging is completed, the packing of the goods is according to customer’s requirement or the general way of export packing. iMW(iMetalwork) professional QC documentary staff will take photos, and the sales staff will send them to the customer, and inform the customer of the packing time.

Types of Scaffolding Steel Prop

Quick Navigation

Get In Touch

-

11/F Winner Building, 36 Man Yue Street,

Hung Hom, Kowloon, Hong Kong - +86 181 550 37937

- info@rock-construction.hk