What is Aluminum Ringlock Scaffolding

iMW(iMetalwork) is the leading supplier of Ringlock Scaffolding materials. With strict quality control, we have served more 100 customers in the worldwide for 10+ years, supplying high-quality scaffolding components for projects ranging from residential, industrial to commercial.

A full size range of components and related accessories are available to meet the needs of every project and application. The components of Ringlock Scaffolding System are pre-fabricated with high strength integrated connections which simplify assemble and reduce labors. All parts of Ringlock scaffolding system are manufactured to high-quality standards with using aluminum alloy extrusions.

Regardless of the regular or customized components you’re looking for, you’ll find the best solutions for your needs.

Aluminum Ringlock Scaffolding System

Ringlock scaffolding system is one of the most popular types of scaffolding systems in the world, also called Ring Lock Scaffolding, Disc Lock Scaffolding or All Round Scaffolding. As a modular scaffolding system, it is extremely versatile, highly economical, more convenient and faster to use.

Why Choose Aluminum Ringlock Scaffolding?

Aluminum Ringlock Scaffolding System joint structure is reasonable, simple production process, easy operation, wide range of use, compared with traditional scaffolding, Aluminum Ringlock Scaffolding System has the following remarkable features:

| Ringlock Features | Details |

| Easy to Stand | Just insert the plugs at both ends of the horizontal rod into the corresponding taper holes on the vertical rod, and then tap it tightly. |

| Simple | Fast and simple to erect with only three component fastenings. |

| Light Weight | Manufactured by aluminum alloy, Aluminum Ringlock scaffolding System is lighter than a standard steel scaffolding tube. |

| Economical | Aluminum Ringlock scaffolding System with only three main components. |

| Fast | 30%-50% faster than traditional scaffolding. |

| Versatile | With 500mm intervals on the verticals, Aluminum Ringlock scaffolding System is extremely versatile for Facade, Shoring Structures, Circular, Birdcages, Staircases, Mobile Towers and etc. |

| Flexible | 0.6m to 3.0m bays using boards or battens. |

Aluminum Ringlock Scaffolding Welding Process

Aluminum Ringlock Scaffolding Details

Aluminum Ringlock Scaffolding Systems Parts

iMW(iMetalwork) provides a high quality range of Ringlock Scaffolding System to customers with needs. The entire range of Ringlock Scaffolding System is perfectly manufactured using high grade raw materials, in compliance with the international quality standards. Moreover, iMW Scaffolding can provide a variety of specifications for these products, in order to meet different requirements of customers. Our product range includes Ringlock Vertical/Standard, Ringlock Ledger/Horizontal, Ringlock Transom, Ringlock Hop-Up Bracket and Ringlock accessories etc.

These are the vertical parts of the scaffold. Aluminum standard is a very popular type of aluminum ringlock scaffolding system as it is very fast to erect.

| Code | Length | Weight | Material | Package |

| ARS30 | 3.0m | 6.1 | Aluminum Alloy Extrusions | Pallets |

| ARS25 | 2.5m | 5.2 | Aluminum Alloy Extrusions | Pallets |

| ARS20 | 2.0m | 4.3 | Aluminum Alloy Extrusions | Pallets |

| ARS15 | 1.5m | 3.4 | Aluminum Alloy Extrusions | Pallets |

| ARS10 | 1.0m | 2.5 | Aluminum Alloy Extrusions | Pallets |

| Code | Length | Weight | Material | Package |

| ARL30 | 3.0m | 4.6 | Aluminum Alloy Extrusions | Pallets |

| ARL24 | 2.4m | 3.9 | Aluminum Alloy Extrusions | Pallets |

| ARL18 | 1.8m | 3.2 | Aluminum Alloy Extrusions | Pallets |

| Code | Length | Weight | Material | Package |

| ARTL12 | 1.2m | 2.6 | Aluminum Alloy Extrusions | Pallets |

| ARTL07 | 0.7m | 1.9 | Aluminum Alloy Extrusions | Pallets |

| ARTL05 | 0.5m | 1.6 | Aluminum Alloy Extrusions | Pallets |

| Code | Length | Weight | Material | Package |

| ARSP30 | 3.0m | 28.2 | Aluminum Alloy Extrusions | Pallets |

| ARSP24 | 2.4m | 22.6 | Aluminum Alloy Extrusions | Pallets |

| ARSP18 | 1.8m | 17.5 | Aluminum Alloy Extrusions | Pallets |

| ARSP15 | 1.5m | 14.8 | Aluminum Alloy Extrusions | Pallets |

| ARSP12 | 1.2m | 12.2 | Aluminum Alloy Extrusions | Pallets |

| ARSP07 | 0.7m | 6.6 | Aluminum Alloy Extrusions | Pallets |

Aluminum Ringlock Scaffolding trapdoor platform are temporary elevated structures for support work crews and materials on construction sites when conducting maintenance or repair.

| Code | Length | Weigh | Material | Package |

| ARAP30 | 3.0m | 28.2 | Aluminum Alloy Extrusions | Pallets |

| ARAP24 | 2.4m | 22.6 | Aluminum Alloy Extrusions | Pallets |

| ARAP18 | 1.8m | 17.4 | Aluminum Alloy Extrusions | Pallets |

| ARAP12 | 1.2m | 12.2 | Aluminum Alloy Extrusions | Pallets |

| Code | Length | Weight | Material | Package |

| ARHP30 | 3.0m | 21.6 | Aluminum Alloy Extrusions | Pallets |

| ARHP24 | 2.4m | 17.4 | Aluminum Alloy Extrusions | Pallets |

| ARHP18 | 1.8m | 13.3 | Aluminum Alloy Extrusions | Pallets |

| ARHP12 | 1.2m | 9.3 | Aluminum Alloy Extrusions | Pallets |

| ARHP07 | 0.7m | 5.1 | Aluminum Alloy Extrusions | Pallets |

Aluminum Ringlock Scaffolding Toe Board is made from aluminum alloy extrusions. With Self Locks at both ends, compatible with Ring Lock System Ledger.

| Code | Length | Weight | Material | Package |

| ARTB30 | 3.0m | 7.6 | Aluminum Alloy Extrusions | Pallets |

| ARTB24 | 2.4m | 6.5 | Aluminum Alloy Extrusions | Pallets |

| ARTB18 | 1.8m | 5.2 | Aluminum Alloy Extrusions | Pallets |

| ARTB12 | 1.2m | 4.1 | Aluminum Alloy Extrusions | Pallets |

| ARTB07 | 0.7m | 2.6 | Aluminum Alloy Extrusions | Pallets |

| ARTB05 | 0.5m | 2.1 | Aluminum Alloy Extrusions | Pallets |

| Code | Length | Weight | Material | Package |

| ARLB79 | 7.9m | 42.6 | Aluminum Alloy Extrusions | Pallets |

| ARLB68 | 6.8m | 36.7 | Aluminum Alloy Extrusions | Pallets |

| ARLB57 | 5.7m | 30.2 | Aluminum Alloy Extrusions | Pallets |

| ARLB46 | 4.6m | 25.1 | Aluminum Alloy Extrusions | Pallets |

| ARLB35 | 3.5m | 20.1 | Aluminum Alloy Extrusions | Pallets |

The vertical intersection of the vertical pole axis line and the horizontal pole axis line of the ringlock scaffolding system has high precision and reasonable force properties. The number of face brace used is much less than that of traditional scaffolding.

| Code | Length | Weight | Material | Package |

| ARFB30 | 3.0m | 5.9 | Aluminum Alloy Extrusions, Steel Casting And Mild Steel | Pallets |

| ARFB24 | 2.4m | 5.3 | Aluminum Alloy Extrusions, Steel Casting And Mild Steel | Pallets |

| ARFB18 | 1.8m | 4.9 | Aluminum Alloy Extrusions, Steel Casting And Mild Steel | Pallets |

| Code | Length | Weight | Material | Package |

| AREB12 | 1.2m | 4.5 | Aluminum Alloy Extrusions, Steel Casting And Mild Steel | Pallets |

| AREB07 | 0.7m | 3.2 | Aluminum Alloy Extrusions, Steel Casting And Mild Steel | Pallets |

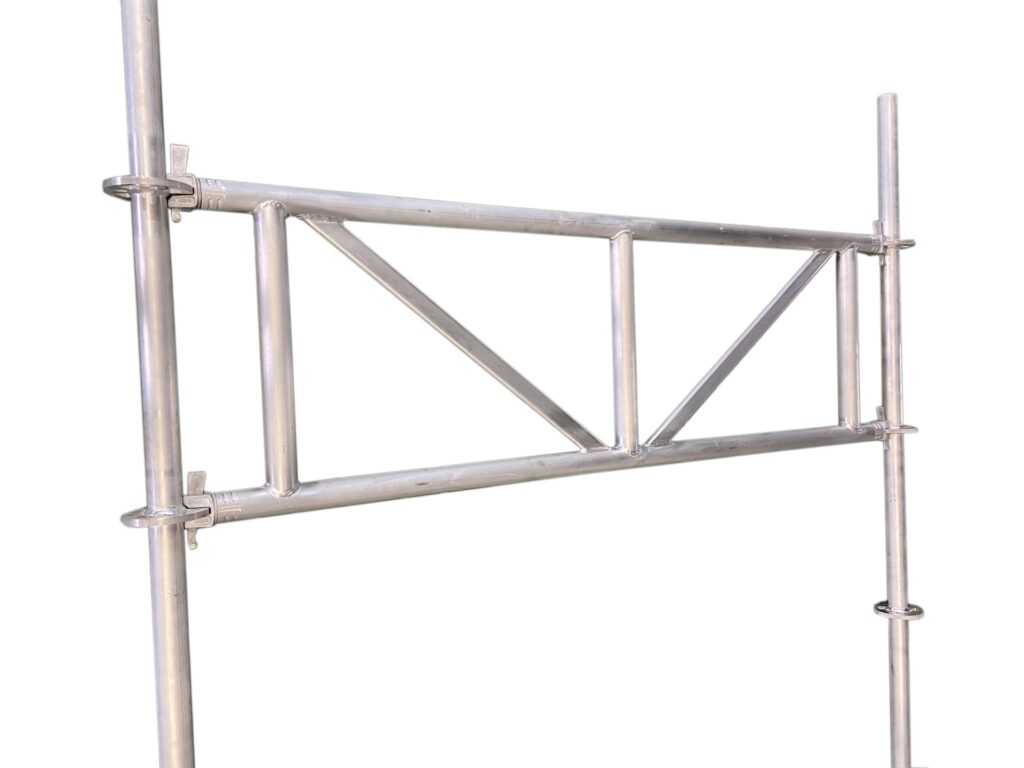

Aluminum Ringlock scaffolding Trusses are horizontal members of Ringlock scaffolding that allow more load compared to ledgers.

| Code | Length | Weight | Material | Package |

| ARTT30 | 3.0m | 13.8 | Aluminum Alloy Extrusions | Pallets |

| ARTT24 | 2.4m | 11.1 | Aluminum Alloy Extrusions | Pallets |

| ARTT18 | 1.8m | 9.2 | Aluminum Alloy Extrusions | Pallets |

Aluminum Ringlock Scaffolding Stretcher stair offers a wide access option. The access scaffold enables workers to easily carry tools and equipment.

| Code | High | Weight | Material | Package |

| ARSS20 | 2.4m*2.0m | 29.5 | Aluminum Alloy Extrusions | Pallets |

| ARCS20 | 2.4m*2.0m | 31.1 | Aluminum Alloy Extrusions | Pallets |

| ARCS15 | 2.4m*1.5m | 27.4 | Aluminum Alloy Extrusions | Pallets |

| ARCS10 | 2.4m*1.0m | 25.1 | Aluminum Alloy Extrusions | Pallets |

| ARCS10a | 1.2m*1.0m | 15.6 | Aluminum Alloy Extrusions | Pallets |

| Code | Length | Weight | Material | Package |

| ARSH20 | 2.0m | 8.1 | Aluminum Alloy Extrusions | Pallets |

| ARSH15 | 1.5m | 5.5 | Aluminum Alloy Extrusions | Pallets |

| ARSH10 | 1.0m | 4.4 | Aluminum Alloy Extrusions | Pallets |

| Code | Length | Weight | Material | Package |

| ARSHTP20 | 2.0m | 4.5 | Aluminum Alloy Extrusions | Pallets |

| ARSHTP15 | 1.5m | 4.7 | Aluminum Alloy Extrusions | Pallets |

| Code | Length | Weight | Material | Package |

| ARLA48 | 4.8m | 16.3 | Aluminum Alloy Extrusions, Aluminum/Steel Casting And Mild Steel | Pallets |

| ARLA43 | 4.3m | 14.9 | Aluminum Alloy Extrusions, Aluminum/Steel Casting And Mild Steel | Pallets |

| ARLA38 | 3.8m | 13.6 | Aluminum Alloy Extrusions, Aluminum/Steel Casting And Mild Steel | Pallets |

| ARLA33 | 3.3m | 12.5 | Aluminum Alloy Extrusions, Aluminum/Steel Casting And Mild Steel | Pallets |

| ARLA30 | 3.0m | 11.8 | Aluminum Alloy Extrusions, Aluminum/Steel Casting And Mild Steel | Pallets |

| ARLA28 | 2.8m | 10.7 | Aluminum Alloy Extrusions, Aluminum/Steel Casting And Mild Steel | Pallets |

| ARLA23 | 2.3m | 9.4 | Aluminum Alloy Extrusions, Aluminum/Steel Casting And Mild Steel | Pallets |

Aluminum Ringlock Scaffolding Advantage

A. High quality materials, higher quality.

Material - The material of the product is made of aluminum alloy extrusions, that is higher than the standard.

Quality assurance, not easy to crush deformation.

B. Advanced technology, better performance.

Products using advanced technology, avoid the production malpractice of old craft, causes the product the anti-deformation and the anti-stretching performance to be stronger, more fits the scaffolding.

C. Anti-rust treatment, longer service life.

After passivation and surface treatment, it is corrosion resistance is better than the ordinary tubes, longer service life.

D. Standard production, more secure.

According to the professional design and advanced technology, quality guarantee, ensure construction safety and personnel safety.

Welding of Aluminum Ringlock Scaffolding Standard

Recommended Products

Quick Navigation

Get In Touch

-

11/F Winner Building, 36 Man Yue Street,

Hung Hom, Kowloon, Hong Kong - +86 181 550 37937

- ali@imetalwork.com