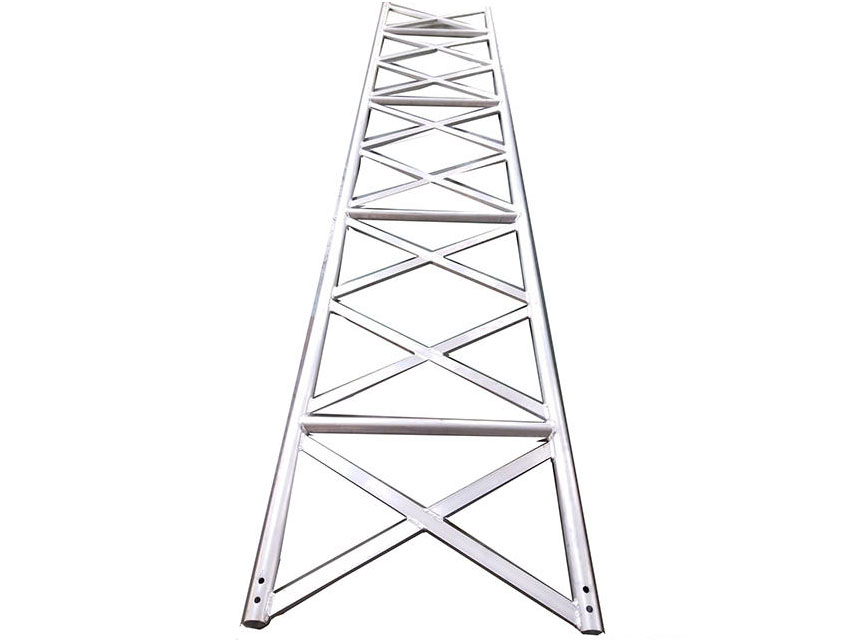

What is Alloy Scaffolding Beam?

Alloy Beams are prefabricated and essential scaffolding components, which are required to carry out certain operations, such as: Forming a bridge in a scaffold structure. Creating suspended platforms. Erecting temporary roofs.

All aluminum beam raw materials are cut, punched, and R-arc cut by laser processing equipment to ensure that the tolerance of the parts is less than 0.2mm; each weld is welded simultaneously by two welders with 16 years of experience in alloy truss welding to ensure the quality of the weld and the greatest possible reduction in distortion.

The alloy beam produced by iMW are favored by customers in Australia, Britain, Ireland and other countries.

Types of Aluminum Beam

High grade aluminium beams for use with 48.3mm tube and fitting scaffolding. Without any compromise in performance, alloy beam offer significant savings on alternative materials. Considerably lighter than steel, alloy beams are faster and easier to erect, thereby saving construction time.

Length | Weight | Width |

2M | 8.5 | 450mm |

3M | 12.5 | 450mm |

4M | 16.5 | 450mm |

5M | 21.0 | 450mm |

6M | 22.5 | 450mm |

8M | 32.5 | 450mm |

Key features include:

Design enables easy connection with fittings to any scaffolding structure.

Less than half the weight of a steel beam.

1.5 times stronger than a steel beam.

Tested to and complies with European Standards.

Connection by 4 bolt spigot system.

Alloy beam also available in 1m, 2m, 3m, 4m and 6m lengths.

Our Aluminium Scaffold Beams are lightweight, high performance, high quality and can be used in all types of scaffold designs. Our alloy beams which are often referred to as lattice beams are lightweight and designed to have a low to mid-level load capacity. Commonly used for simple bridging and cantilever scaffolding solutions.

Our alloy beams has the smallest depth and are the lightest to handle of our alloy beams weighing approx. 5.0Kg/m, they can be connected to form longer spans using our beam connection spigots and quick release spring pins.

Fully compatible with regular outer diameter scaffolding tube and fittings along with other alloy beams.

The aluminum X-beam’s quick fit connecting system using spring clips and spigots also means easy assembly, providing another advantage over traditional style scaffolding.

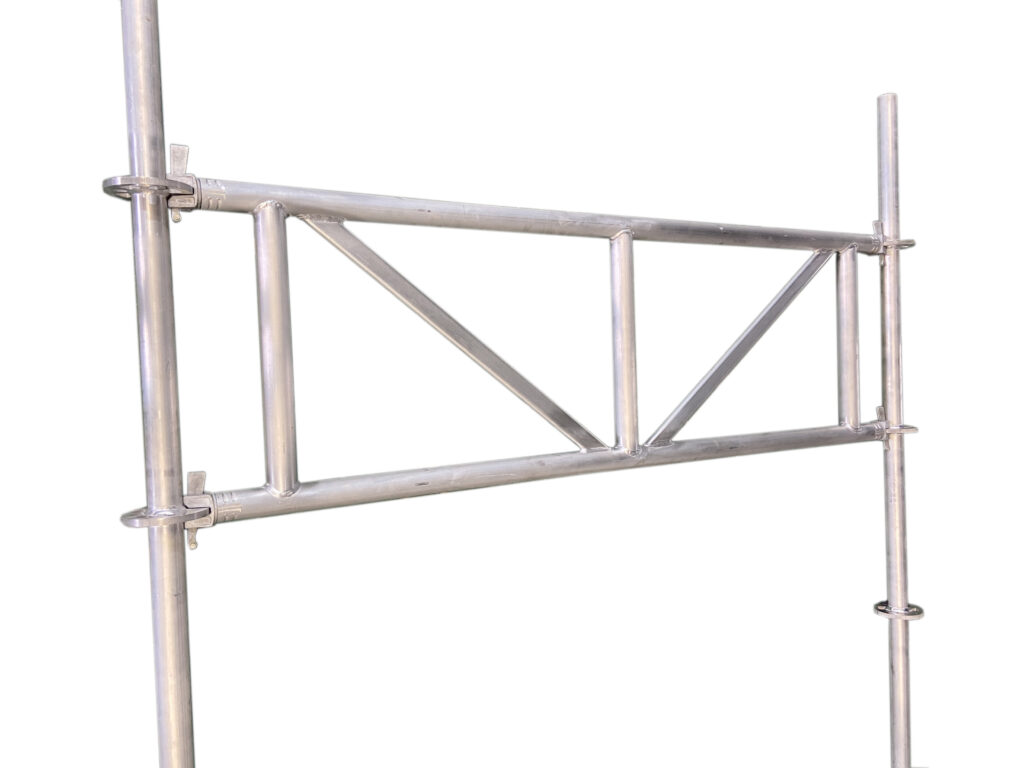

TRUSS TRANSOM, Heavy duty transom, Transom Truss

Aluminum transon truss are horizontal members of Ringlock scaffolding that allow more load compared to ledgers.use for build on walk wall.

Code | Length | Weight | Material | Package |

ARTT30 | 3.0m | 13.8 | Aluminum Alloy Extrusions | Pallets |

ARTT24 | 2.4m | 11.1 | Aluminum Alloy Extrusions | Pallets |

ARTT18 | 1.8m | 9.2 | Aluminum Alloy Extrusions | Pallets |

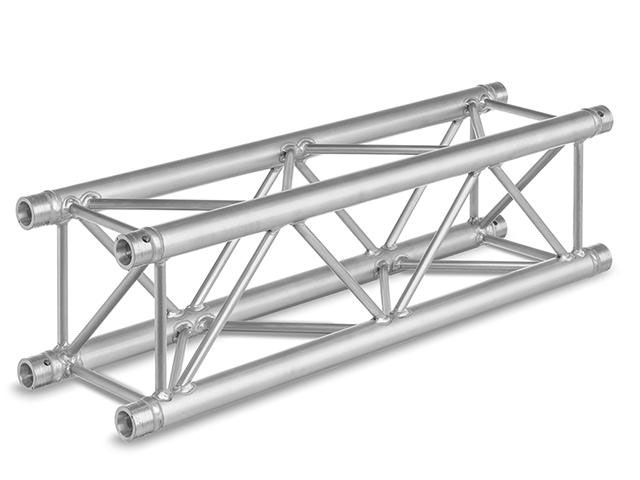

A quick and easy-to-use alloy truss system for a variety of needs. Alloy truss offers significantly reduced assembly/breakdown time and trouble-free installation. Solid conical connectors and tapered pins ensure ease of use and secure connections. Custom designs upon request.

Key benefits

1.Compact display series system

2.Connection kit supplied with every aluminum truss length or junction

3.Lightweight, modular construction

4.Compatible with cell 100 series

5.Fast connection for quick, simple and secure assembly

6.Compatible with alloy truss accessories

7.Impressive free-span characteristics for its size

8.Powder coat color finish available on request

Automatic Welding of Aluminum Beam

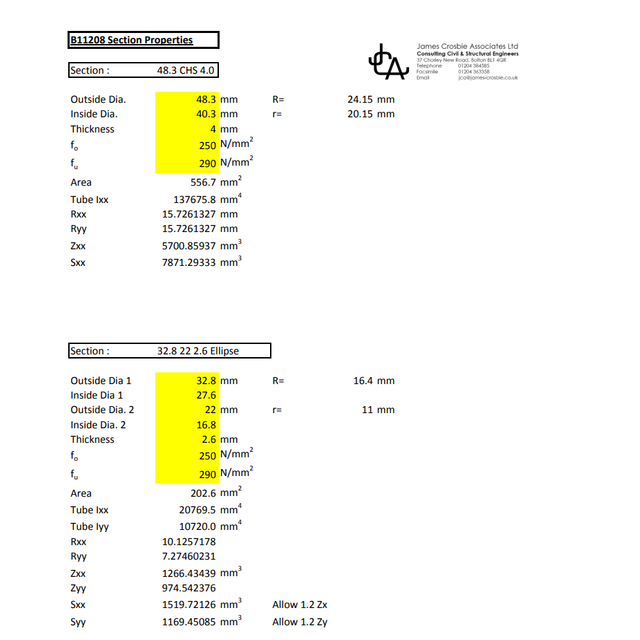

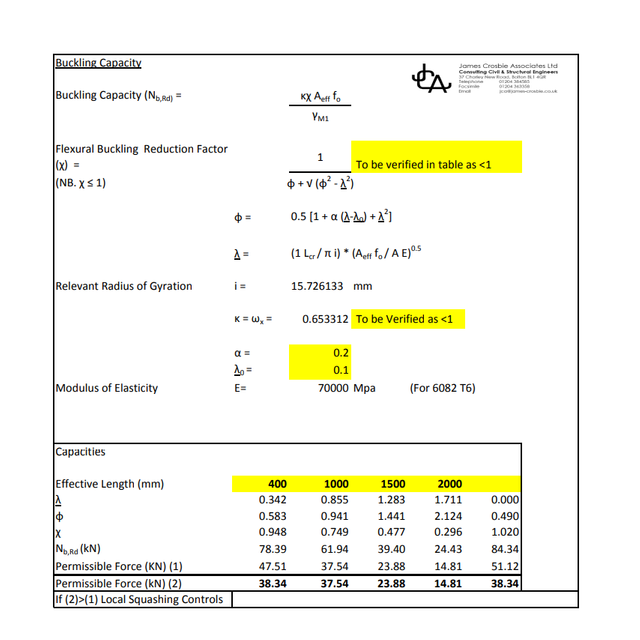

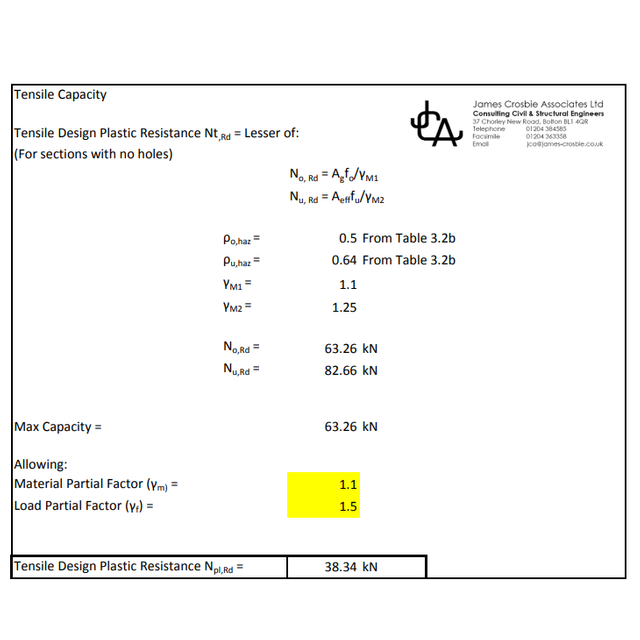

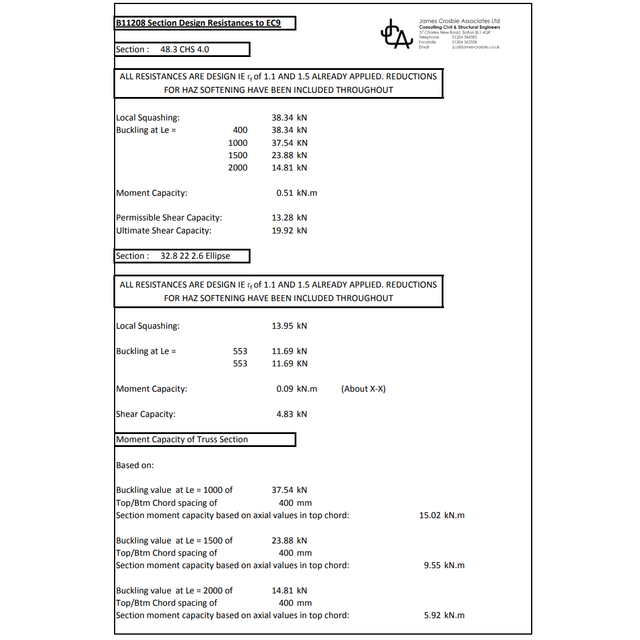

Test Report

Alloy Beam VS Steel Beam

The Advantage of Alloy Beam

1.Design enables easy connection with fittings to any scaffolding structure.

2.Less than half the weight of a steel beam.

3.1.5 times stronger than a steel beam.

4.Tested to and complies with European Standards.

5.Connection by 4 bolt spigot system.

6.Alloy beam also available in 1m, 2m, 3m, 4m and 6m lengths.

Recommended Products

Quick Navigation

Get In Touch

-

11/F Winner Building, 36 Man Yue Street,

Hung Hom, Kowloon, Hong Kong - +86 181 550 37937

- info@rock-construction.hk