Tunnel Engineering

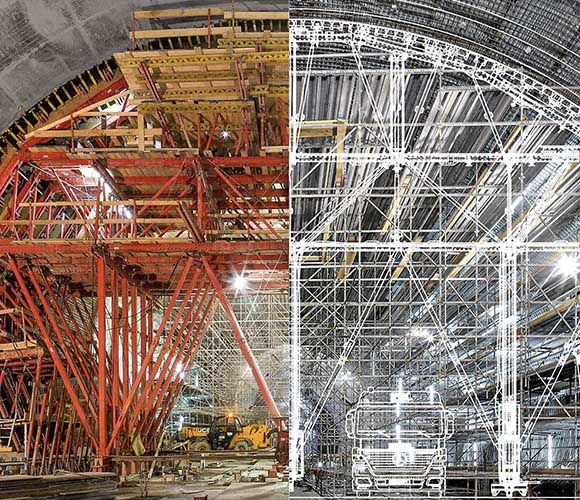

iMW(iMetalwork) scaffolding is widely used in the bridge and tunnel engineering.

Because bridge and tunnel engineering is usually difficult and has a long construction period, the performance and quality of scaffolding products is usually highly valued. As one of the best-selling products of iMW, iMW scaffolding systems such as Ringlock, Cuplock and etc. has been well received in the industry and has been widely used in the construction of bridge-tunnels. iMW scaffolding systems features high safety, easy disassembly, and corrosion resistance.

Nowadays, increasingly congested urban traffic has brought a lot of inconvenience to people’s travel. But relying on iMW high-quality scaffolding products, many bridges and tunnels have sprung up. While greatly alleviating the traffic congestion situation, it also shows the strength of iMW is strong enough.

We believe that because of our continuous adherence and improvement of product quality, we have the iMW scaffolding products exported to countries around the world.

Construction Engineering

In construction engineering scaffolding system products play no doubtly a very important role. As a company that has been immersed in the scaffolding industry for nearly a decade, the scaffolding products of iMW(iMetalwork) is well-known overseas and widely acclaimed.

Through the combination of various types of scaffolding couplers, steel pipes and planks of iMW(iMetalwork), the safety and efficiency of building construction are greatly increased while reducing the procurement cost of customers.

In addition, the various scaffolding systems of iMW(iMetalwork) is also very reliable. Ringlock system, Cuplock system, Kwikstage system, and many other systems for the customer to choose. While meeting the diverse architectural needs of our customers, customers have significantly reduced labor costs. Product performance is reliable, escorting the safety of every worker.

iMW(iMetalwork), don’t forget the heart, remember the mission. While continuously expanding the scope of product management, we also concentrate on solving problems for each customer.

The development of the country is inseparable from the construction of infrastructure. With the support of iMW(iMetalwork), many high-rise buildings are emerging all over the world.

Offshore Petroleum Engineering

iMW(iMetalwork) products are equally significant to the petrochemical engineering. The scaffolding system required by the petrochemical industry has always been one of the advantage products of iMW(Metalwork), such as Cuplock System, Ringlock System and etc. In addition, iMW’s business scope also includes scaffolding couplers, steel pipes, planks, scaffolding accessories, and other products.

The petrochemical industry is a dangerous goods industry with extremely high requirements for the scaffolding system used. It is not only a requirement for product quality, but also for product design and performance. The scaffolding system required by the petrochemical industry must comply with domestic and international safety standards and can not produce any safety accidents in high-altitude operations.

Excellent product design and product quality, corrosion resistance, safety and reliability, easy to move, and product compliance with domestic and international safety standards for construction are important reasons for the extensive use of iMW scaffolding products in petrochemical engineering.

iMW develops for fourteen years and constantly breaks through itself. With quality products and good service, we will let iMW products appear in every corner of the world in the future.

Shipbuilding Engineering

iMW(iMetalwork) Scaffolding products are widely used in Shipbuilding engineering. In the process of ship construction and maintenance, all kinds of iMW scaffolding system can be well adapted to the requirements of different ships.

As a working platform for workers in the process of ship maintenance or construction, iMW scaffolding system can not only ensure the safety and reliability of use but also ensure the convenience and flexibility of installation and disassembly. At the same time, it can also meet the requirements of ship linearity and structure.

Therefore, the application of iMW scaffolding products in ships has the following five characteristics:

1. Ensure personal safety

2. Guarantee construction quality

3. Speed up the construction schedule

4. Ensure the continuity of construction procedures

5. Cheaper labor and material cost

Nowadays, iMW continues to expand its product range to meet the needs of different customers. Existing business scope includes System Scaffolding of Ringlock,Cuplock,Kwikstage,Frame; Steel props,Steel planks,Steel pipes,and Scaffolding & Formwork accessories.

We hope that with excellent product quality of iMW, every ship can safely sail to its destination.

Aircraft Engineering

Ensuring the safety of passengers is the most important responsibility and concern of the aviation industry. Therefore, frequent maintenance, inspections, and repairs of aircraft are required. Scaffolding products such as aluminum tripods, aluminum towers, aluminum beams, and aluminum ladders are often used in aircraft maintenance and repair work.

iMW scaffolding is suitable for regular maintenance or repair of aircraft nose, fuselage, wing, passenger cabin, and other components, such as painting, cleaning, mechanical and electrical system overhaul, modification, disassembly, and replacement of components.

iMW Aluminum Scaffolding has the characteristics of lightness, quick assembly, safety and durability, and high-cost performance.

Our dealers have cooperated with aircraft maintenance companies many times and gave us the best feedback.

Widely used in hangars, airports, aircraft maintenance, ultra-high-altitude operating environments, and even interior decoration

Quick Navigation

Get In Touch

-

11/F Winner Building, 36 Man Yue Street,

Hung Hom, Kowloon, Hong Kong - +86 181 550 37937

- info@rock-construction.hk