Leading Supplier of Cuplock Scaffolding System

iMW(iMetalwork) is the leading supplier of Cuplock Scaffolding materials. With strict quality control, we have served more 100 customers in the worldwide for 10+ years, supplying high-quality scaffolding components for projects ranging from residential, industrial to commercial.

Cuplock Scaffolding System is the most commonly used system scaffolding in the world. The official name of this scaffolding system is Cuplok, but most people know it as Cuplock. iMW Cuplock Scaffolding System is used for support and access structures in construction industry, offshore construction, industrial maintenance, and ship building. And all Cuplock Scaffolding System parts are designed and manufactured to meet all scaffolding industry standard.

Cuplock Scaffolding System has quick locking and fastening devices that simplify the construction process and make it safer for workers to participate in construction. All of these are good ways to optimize the work efficiency of construction projects and improve the construction safety index.

What is Cuplock Scaffolding?

Cuplock Scaffolding System, is a scaffold system that uses the “Cup” and “Blade” to lock the vertical/standard and horizontal/ledger together, and lock the blades by twisting the cup. This Cuplock Scaffold System uses no nut, bolt or wedge. Cuplock’s Scaffolding System node-point is revolutionary, and makes it faster and easier than any other scaffolding system.

Why Choose Cuplock?

Cuplock Scaffolding System joint structure is reasonable, simple production process, easy operation, wide range of use, compared with traditional scaffolding, Cuplock Scaffolding System has the following remarkable features:

| Cuplock Features | Details |

| Easy to Stand | No nut and bolt or wedge, just lock the blade into cup at each node on the standard. |

| Sample | Fast and simple to erect with only four component fastenings. |

| Light Weight | Manufactured using 3.2mm thickness high grade steel, Cuplock Scaffolding System is 20% lighter than standard 4mm thickness scaffolding tube. |

| Economical | Cuplock Scaffolding System with only three main components. |

| Fast | 30%-50% faster than traditional scaffolding. |

| Durable | Hot-Dip-Galvanized provides a low maintenance, long life. |

| Versatile | With 500mm cup intervals on the verticals, Cuplock Scaffolding System is extremely versatile Facade, Shoring Structures, Circular, Birdcages, Staircases, Mobile Towers and etc. |

| Flexible | 0.6m to 3.0m bays using boards or battens. |

Cup-Locking Procedure:

Here below are pictures showing how to install the Cuplock Scaffolding System:

1、Locate the ledger blade into the bottom cup.

2、Slide the top cup down the standard and rotate.

3、Tighten with a hammer blow.

4、A cuplock’s node-point completed.

Cuplock Scaffolding Systems Parts

iMetalwork Scaffolding provides a high quality range of Cuplock Scaffolding System to customers with needs. The entire range of Cuplock Scaffolding System is perfectly manufactured using high grade raw materials, in compliance with the international quality standards. Moreover, iMetalwork Scaffolding can provide a variety of specifications for these products, in order to meet different requirements of customers. Our product range includes Cuplock Vertical/Standard, Cuplock Ledger/Horizontal, Cuplock Transom, Cuplock Hop-Up Bracket and Cuplock accessories etc.

Cuplock Scaffolding Systems Parts manufactured by iMW

Spigoted Standard / Vertical

These cuplock scaffolding standards are used in conjunction with integral spigots, 150mm long, are provided at the top of each for making vertical connections. The spigots are drilled to receive locking pins, when it is necessary to resist minor tensile forces between standard members.

Cuplock Scaffolding Spigoted Standard / Vertical Steel Tube: 48.3*3.2mm | |||||

| Code | Item | Length | Weight | ||

| iMW-CLS001 | Cuplock Spigot Standard | 0.5 M | 1’8” | 3.40 KG | 7.50 LBS |

| iMW-CLS002 | Cuplock Spigot Standard | 1.0 M | 3’3” | 6.10 KG | 13.45 LBS |

| iMW-CLS003 | Cuplock Spigot Standard | 1.5 M | 4’11” | 8.72 KG | 19.22 LBS |

| iMW-CLS004 | Cuplock Spigot Standard | 2.0 M | 6’6” | 11.34 KG | 25.00 LBS |

| iMW-CLS005 | Cuplock Spigot Standard | 2.5 M | 8’2” | 13.95 KG | 30.75 LBS |

| iMW-CLS006 | Cuplock Spigot Standard | 3.0 M | 9’10” | 16.57 KG | 36.53 LBS |

| Specifications can be customized according to requirements. | |||||

Spigotless Standard / Vertical

These standards have no spigot, this combination of components will cater for all extended soffit heights, but for lower heights just spigotless design allows the insertion of jacks with various head components to meet the requirements of differing support applications such as aluminum beam support or decking systems.

Cuplock Scaffolding Spigotless Standard / Vertical Steel Tube: 48.3*3.2mm | |||||

| Code | Item | Length | Weight | ||

| iMW-CLS007 | Cuplock Spigotless Standard | 0.8 M | 2’7” | 4.56 KG | 10.05 LBS |

| iMW-CLS008 | Cuplock Spigotless Standard | 1.3 M | 4’3” | 7.18 KG | 15.83 LBS |

| iMW-CLS009 | Cuplock Spigotless Standard | 1.8 M | 6’ | 9.79 KG | 21.58 LBS |

| iMW-CLS010 | Cuplock Spigotless Standard | 2.3 M | 7’6” | 12.41 KG | 27.36 LBS |

iMW-CLS011 | Cuplock Spigotless Standard | 3.0 M | 9’9’’ | 15.70 KG | 34.61 LBS |

| Specifications can be customized according to requirements. | |||||

Cuplock Ledger / Horizontal

Cuplock Ledgers are manufactured from 48.3*3.0mm scaffolding tube with forged steel blade ends which locate into bottom cups of the standards and are locked in place by the corresponding top cups. Ledgers are available in various lengths to provide the desired grid specification for scaffolding or formwork.

Cuplock Scaffolding Ledger / Horizontal Steel Tube: 48.3*3.0mm | |||||

| Code | Item | Length | Weight | ||

| iMW-CLL001 | Cuplock Ledger | 0.6 M | 2’ | 2.35 KG | 5.18 LBS |

| iMW-CLL002 | Cuplock Ledger | 1.0 M | 3’3” | 3.75 KG | 8.27 LBS |

| iMW-CLL003 | Cuplock Ledger | 1.5 M | 4’11” | 5.47 KG | 12.06 LBS |

| iMW-CLL004 | Cuplock Ledger | 2.0 M | 6’6” | 7.21 KG | 15.90 LBS |

| iMW-CLL005 | Cuplock Ledger | 2.5 M | 8’2” | 8.93 KG | 19.69 LBS |

| Specifications can be customized according to requirements. | |||||

Cuplock Transom

Cuplock transoms are manufactured from 48.3*3.2mm scaffolding tube and designed to provide intermediate support for standard scaffold walk boards by spanning between the inner and outer ledgers.

Cuplock Scaffolding Transom Steel Tube: 48.3*3.2mm | |||||

| Code | Item | Length | Weight | ||

| iMW-CLT001 | Cuplock Transom | 0.56 M | 1’10’’ | 3.79 KG | 8.36 LBS |

| iMW-CLT002 | Cuplock Transom | 0.80 M | 2’7” | 4.67 KG | 10.30 LBS |

| iMW-CLT003 | Cuplock Transom | 1.30 M | 4’3” | 6.50 KG | 14.33 LBS |

| iMW-CLT004 | Cuplock Transom | 1.80 M | 6’ | 8.33 KG | 18.36 LBS |

| Specifications can be customized according to requirements. | |||||

Cuplock Brace / Diagonal

Cuplock braces are manufactured from 48.3*3.2mm scaffolding tube and each brace has two swivel blade ends. Their function is to provide transverse and longitudinal bracing to scaffold structures.

Cuplock Scaffolding Brace / Diagonal Steel Tube: 48.3*3.2mm | |||||

| Code | Item | Length | Weight | ||

| iMW-CLB001 | Cuplock Brace | 1.5*1.8M | 4’11’’*6’ | 8.70 KG | 19.18 LBS |

| iMW-CLB002 | Cuplock Brace | 1.8*2.0M | 6’*6’6’’ | 9.80 KG | 21.60LBS |

| iMW-CLB003 | Cuplock Brace | 1.5*2.5M | 4’11”*8’2’’ | 10.70 KG | 23.59 LBS |

| iMW-CLB004 | Cuplock Brace | 2.0*2.5M | 6’6”*8’2’’ | 11.50 KG | 25.35 LBS |

| iMW-CLB005 | Cuplock Brace | 2.0*3.0M | 6’6’’*9’10’’ | 13.00 KG | 28.66 LBS |

| Specifications can be customized according to requirements. | |||||

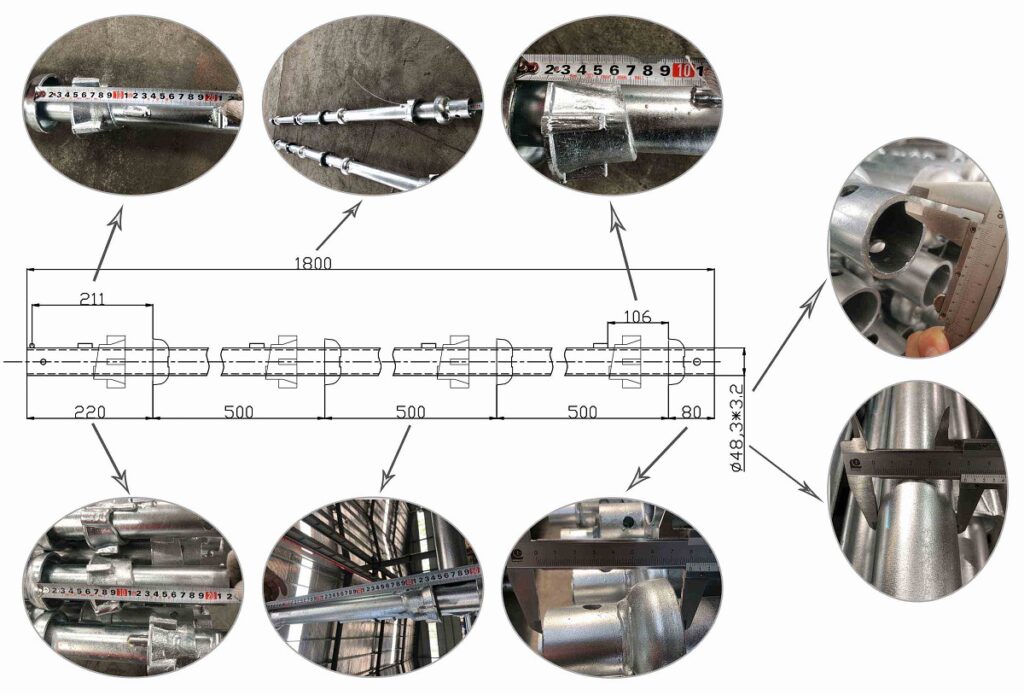

Cuplock Scaffolding Inspection

iMW Scaffolding’s professional QC will make detailed measurements based on the drawings confirmed with customers after scaffold cuplock products come out, so as to ensure that the size of cuplock scaffolding products meets customer requirements.

Cuplock Scaffolding Inspection

iMW Scaffolding – Before cuplock product packaging, professional quality inspection personnel will randomly extract components of Cuplock Scaffolding system from the products purchased by customers for installation and testing, so as to check whether the product can be used normally.

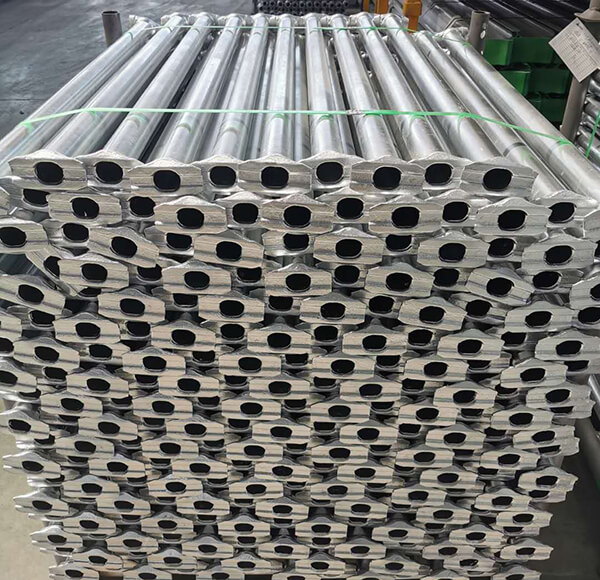

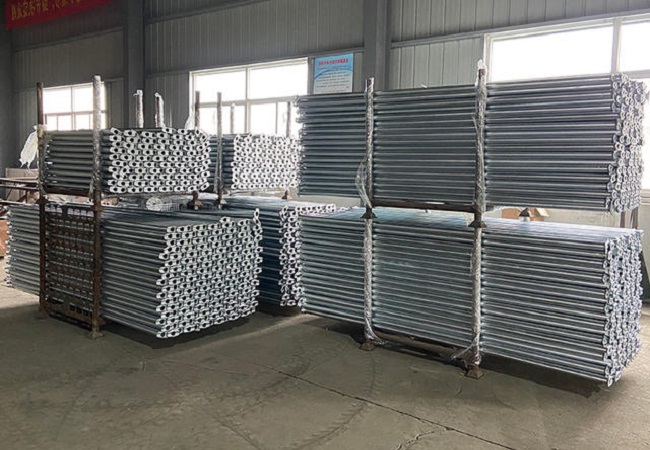

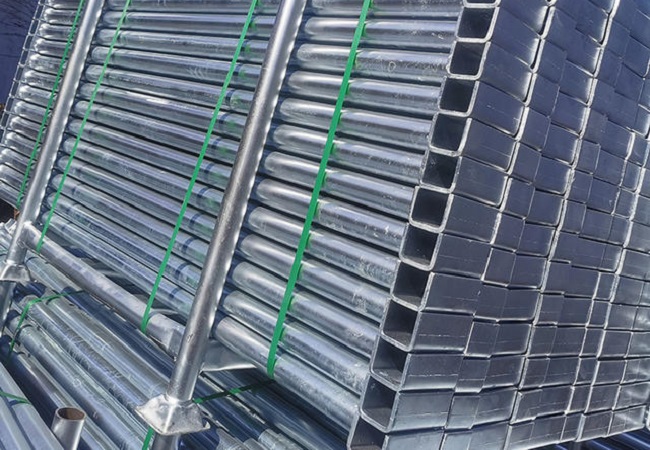

Bulk Cuplock Scaffolding System

When the production and packaging of a batch of cuplock scaffolding system products required by the customer are completed, we will take photos and keep files and send them to the customer, inform the loading time of this batch of scaffold cuplock and let the customer know the shipping schedule.

Bulk Cuplock Scaffolding System

iMW Cuplock Scaffolding vertical welding is mainly divided into three steps:

1. Adjust the tooling equipment distance and determine the bottom cups interval. Use spot welding to fix the bottom cups and located pins to the vertical tube.

2. Located pins full weld, that make sure the located pins are firmly fixed to the vertical tube.

3. Bottom cups full weld, that to ensure the stability of the bottom cups and ensure the safety index in the construction and use.

Cuplock Automatic Welding

Cuplock Welding

FREE for Download and Inquiry

Cuplock Scaffolding Catalogue

Here is catalogue of iMW cuplock scaffolding system. You can see all our cuplock scaffolding diagonal brace, cuplock scaffolding ledger and cuplock scaffolding standard products here.

Projects of Cuplock Scaffolding System

The versatility and wide range of cuplock makes it an ideal system for almost any situation. From the simple residential building project to the most complex access and support structures, it can follow curves and complex contours and is also suitable for many industrial maintenance situations.

Cuplock for Curved Structures

Cuplock Scaffolding System is ability to allow ledgers / horizontals to lock into the standards / verticals from any angle. Because of variable Cuplock Scaffolding System sizes curved structures using can be easily and well realized.

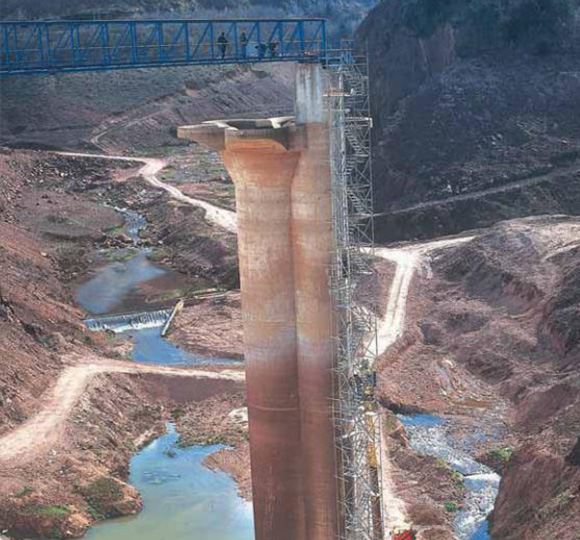

Cuplock for Support Structures

Cuplock Scaffolding System is widely used to create scaffolding support structures. Outrigger load carrying capacity of this cuplock system is very high. And the range of components allows the system to respond virtually and support applications.

Cuplock for Staircase Towers

The Cuplock Staircase tower incorporates special staircase components in the traditional Cuplock tower to create a safe, user-friendly access solution and is quick and easy to install.

Recommended Products

Quick Navigation

Get In Touch

-

11/F Winner Building, 36 Man Yue Street,

Hung Hom, Kowloon, Hong Kong - +86 181 550 37937

- info@rock-construction.hk